# Heat-sink: Parts of thermal system on LED which have function to transfer heat away (by conduction or convection) from sensitive components, such as dies & electronics.

# Die (or Chip): Small-block of semiconductor materials which emitting the light, as main part in fabrication of LED circuit.

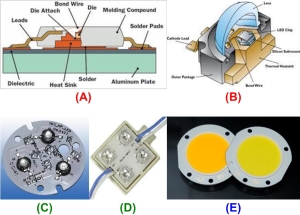

# Packages >> (A) & (B):

Single/discrete components which encapsulating one or more LED die(s); possibly be equipped by optical elements and have thermal, mechanical & electrical interfaces.Power source & bases (as standardized per IEC 62560) are not incorporated into this device, because it cannot be connected directly to the branch of circuit.

# Arrays or Modules >> (C) & (D):

LED light source without having caps, incorporating one or more LED package(s) on PCB (printed circuit board), and possibly including one or more of the following components, interfaces & control-gears: electrical, optical, mechanical & thermal. Power sources (based on ANSI standard) are not incorporated into this device.LED modules are generally designed as replaceable built-in parts into luminaires, boxes, or enclosures; and not intended to be mounted at the outside of them (without special precautions).

# Circuit On Board (COB) >> (E):

LED arrays which is constructed (assembled) with dies on PCB.

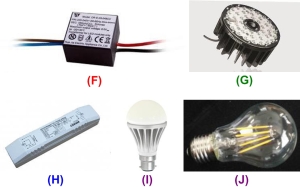

# Control Gear >> (F):

Electronic components which is designed to control a power source by adjusting output voltage, current or duty cycle; to switch the amount & characteristics of electrical energy, which is delivered to the LED packages (components) or arrays (modules).LED control circuitry does not include a power source!

# Light Engine >> (G):

Integrated assembly which is comprised of LED packages, arrays, drivers, and other optical, thermal, mechanical & electrical components. This device is intended to connect directly to the branch circuit, through custom connector that is compatible to the luminaires (for which it was designed and does not use the ANSI standard base).# Drivers >> (H):

The devices that comprised to a power source & control circuitry, which is designed to operate LED packages, arrays, or lamps.# Self-ballasted (integrated) lamps >> (I) & (J):

LED lamps that incorporating control gear & additional elements (which is necessary for stable operation of the light source), and designed for direct connection to the supply voltage.

# Retrofit lamps: LED lamps that intended as replacement for non-LED lamps, without requiring internal modification for the luminaires.

# Non-integrated lamps >> (K):

Assembling devices that comprised of LED arrays, packages & ANSI standard bases. This is intended to connect with the driver of luminaires (through ANSI standard lamp-holder/socket), but cannot be connected directly to the branch circuit.This may include LED replacement for low-voltage halogen lamps.

# Semi-integrated lamps >> (L):

LED lamps which carry the control unit (gear), but operated by separated power supply.# Luminaires >> (M) & (N):

Complete lighting unit that consisting of LED-based elements (packages, arrays, engines, or lamps – including panels) & matched-driver; together with the other parts for distributing light, positioning & protection, and connecting directly to the branch circuit.Some luminaires may be non-repairable (factory-sealed), which cannot be dismantled without being permanently damaged.

Source:

Equipment Energy Efficiency (E3) Program,

Department of Industry & Science,

Commonwealth of Australia

© 2015

“Product Profile: Light Emitting Diodes (LEDs)”

LED Lighting in Australia & New Zealand

Filed under: Alam Takambang Jadi Guru | Leave a comment »